#9 Hands Free Operation Options

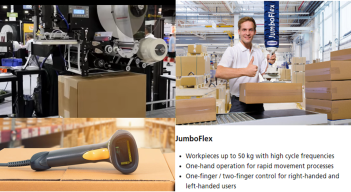

Interesting in reducing the handling of material in your supply chain? 9. Hands Free OperationsAre there manual processes in your operation that could be automated to take the “personal touch” out of the equation? Manually applying labels? Consider adding automatic label applicators PANDA is an acronym for Print and Apply. Print and applying labels by using automated equipment will reduce at least one touch point for your operators. As your company starts to get back to work, reducing the touches on product in your facility helps in many ways. The reduced contact helps your employees stay safe and healthy as well as reducing the risk of spreading any contagious virus to your customers. KVK Inc. has multiple years of successful applications of PANDA to manufacturing, Distribution, and Fulfillment operations. KVKnet.com Vacuum lifters – machine touches the product, not human hands so less contamination Schmalz is a leader in the use of vacuum to reduce the ergonomic need to touch the product. Multiple products offer simple one-hand operations with one-finger/two-finger controls for right or left hand operators. Automated bar code scanners vs. hand operated scanners Although bar code scanners are not new, the use of these robust devices allows operators to effectively work with less touches of packages or totes during the pick process. Contact us today to review how we can add touch-less Print and Apply label systems. Vacuum lifters, or Scanners to your process.